Mechanical Engineering Major

During my college career, I have maintained a 3.09 overall GPA and a 2.28 Mechanical Engineering GPA. Many of my classes have been communication intensive course as part of LSU’s Communication across the Curriculum program so many of my courses have required final projects using different communication: technical, visual, written and oral. Below is a high light of some of the classes I’ve taken and projects I have done. Attached is a flowchart with all of the required courses to earn a mechanical engineering degree at LSU. My degree audit is also attached detail the course I have completed and requirements I have left to complete to earn my degree.

ME 4243 - Capstone I

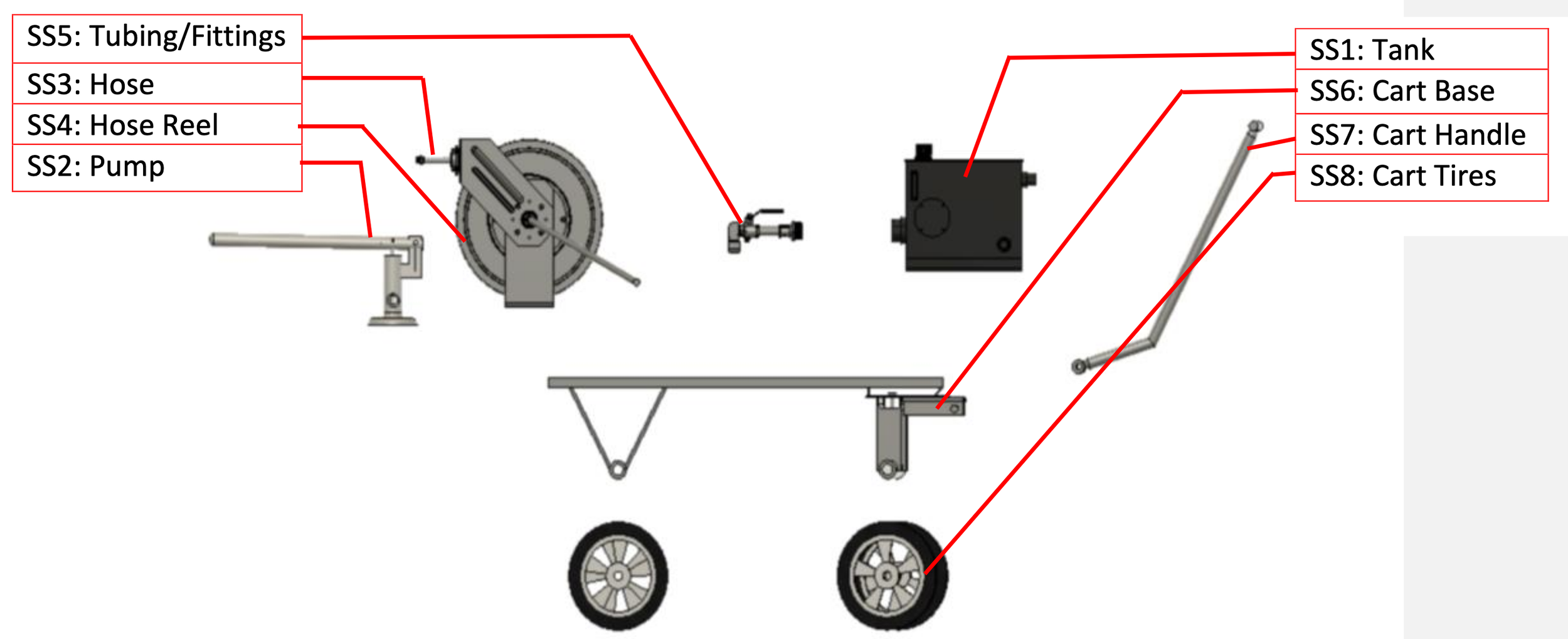

Capstone I is the first part of a two-semester long project that all mechanical engineering students take during their last year at LSU. Students are assigned a team and a project. I was assigned a Mechanical Seal Pot Refilling Skid for ExxonMobil along with three other team members. I was appointed team lead so in addition to designing, I am in charge of creating a schedule and keeping the team on schedule. Our team did an on site visit to meet the operators who will be using the skid. After meeting with the user, our team came up with a design that will be safe and easy to use and maintain. During the design phase, I calculated rolling force of the cart and potential impact force on the cart and the bolts mounting the various components to the cart. In the upcoming weeks, my team will begin ordering components and devising a testing plan for our design. We will finish our skid along with a manual detailing how to safely use and maintain the skid. At the end of the semester, my team presented our project to a panel of industry experts. Using the critiques from the panel, our team will make a few small adjustments before we begin manufacturing our project this upcoming semester.

Team presenting our final design to the panel

Exploded View of Final Design

Final Design Poster

ME 4244 - Machine Design II

Machine Design II is a course consisting of strength consideration and component design. The class did an overview on stress analysis, loading, failure theories and fatigue. This course required students to look deeper into a concept and create a laboratory experiment that the department might use in the future. My team chose to create a lab that showed how stress concentrations can affect a sample beam. The details of this assignmnet can be view by downloading the Report File.

ME 4611 - Thermal Systems Labratory

ME 4611 is a laboratory based class where groups cycle through five different experiments: Clapeyron, Bomb Calorimeter, Refrigeration Cycle, Jet Engine, and Rankine Cycle. This class focuses on not only learning but being able to present what you have learned and apply that knowledge during on the spot questioning. Every other week groups run an experiment and answers questions from peers called “Table Topics.” During non-experiment weeks students present on either their experiment or a special topic of their choosing. For each experiment, one student presents on the experimental procedure and pre-lab calculations and another student presents the results of the experiment. Each week the presentations and table topic session were recorded so that students can look over their presentation skills and improve on them. The videos can be seen in the playlist featured here or clicking the Youtube symbol below.

ME 3603 - Instrumentation and Measurements

ME 3603 is a course that goes over different measurement systems, probability, statistics, and uncertainty analysis. Additionally, this class has a lab component that reinforces what is being taught the lab topics were as follows: Probability and Statistics, Static Calibration and Regression Analysis Fundamentals of Data Acquisition, Spectral Analysis, Signal Conditioning, Rotor Calibration and Frequency Measurements, Strain Measurements and 1st Order Systems, and Temperature Measurements and 2nd Order Systems. Through out the semester, I reported on my experiment results through data sheets, technical memos, and formal lab reports. The data sheet was prepared individually and the technical memos and formal lab reports were completed as a group.

ME 3633 - Manufacturing Processes & Methods

Steel Stool Frame Welds by Me

ME 3633 is a class that goes over modern manufacturing processes such as welding, machining, metal casting, and CAD/CAM operations. Outside of the class room, students completed three projects in the machine shop. Students created a steel pin using turning operations, a steel stool using welding operations, an mini heat exchanger using CNC operations. A final report written by the lab group gives details of each operation.

ME 2212 - Introduction to Mechanical Engineering Design

ME 2122 is an entry level design class for underclassmen students to understand the design process. The course goes over reverse engineering, design methodologies, product realization, ethics, and professional development. While learning about reverse engineering, students are tasked with completing a tear down report for an item of their choice. I chose to tear down a flatiron for hair. Through this experiment I learned how flat irons worked and why the manufacturer chose the design. As a final project, this class requires students to work with a random team to design a solution to a problem. My team was assigned to design a way to shuffle oversized cards used. Out team looked at many different card shuffler designs and came up with a design that used gravity to have the cards fall together randomly.